Material Data Sheet

Heritage Sour Service - SM-C110T

SM-C110T is a low alloy Carbon steel OCTG material suitable for severe Sour Service applications while providing enhanced and guaranteed Collapse resistance compared to API ratings. SM-C110T is a Sulfide Stress Cracking (SSC) resistant material, which production order is delivered with both SSC and Collapse proof tests.

SM-C110T is equivalent to SMC110, produced using the same manufacturing route as SM-C110 with additional controls meant to achieve higher collapse resistance.

SM-C110T derived from the combination of SMI's unrivaled know-how in mastering both High Collapse and Sour Service technologies, interlocked with best-in-class quality control. SM-C110T has no equivalent in API 5CT/ ISO 11960 grades and in order to achieve its superior Sour Service properties Nippon Steel applies a very strict QA/QC throughout its manufacturing route from Steel Making to Heat Treatment process.

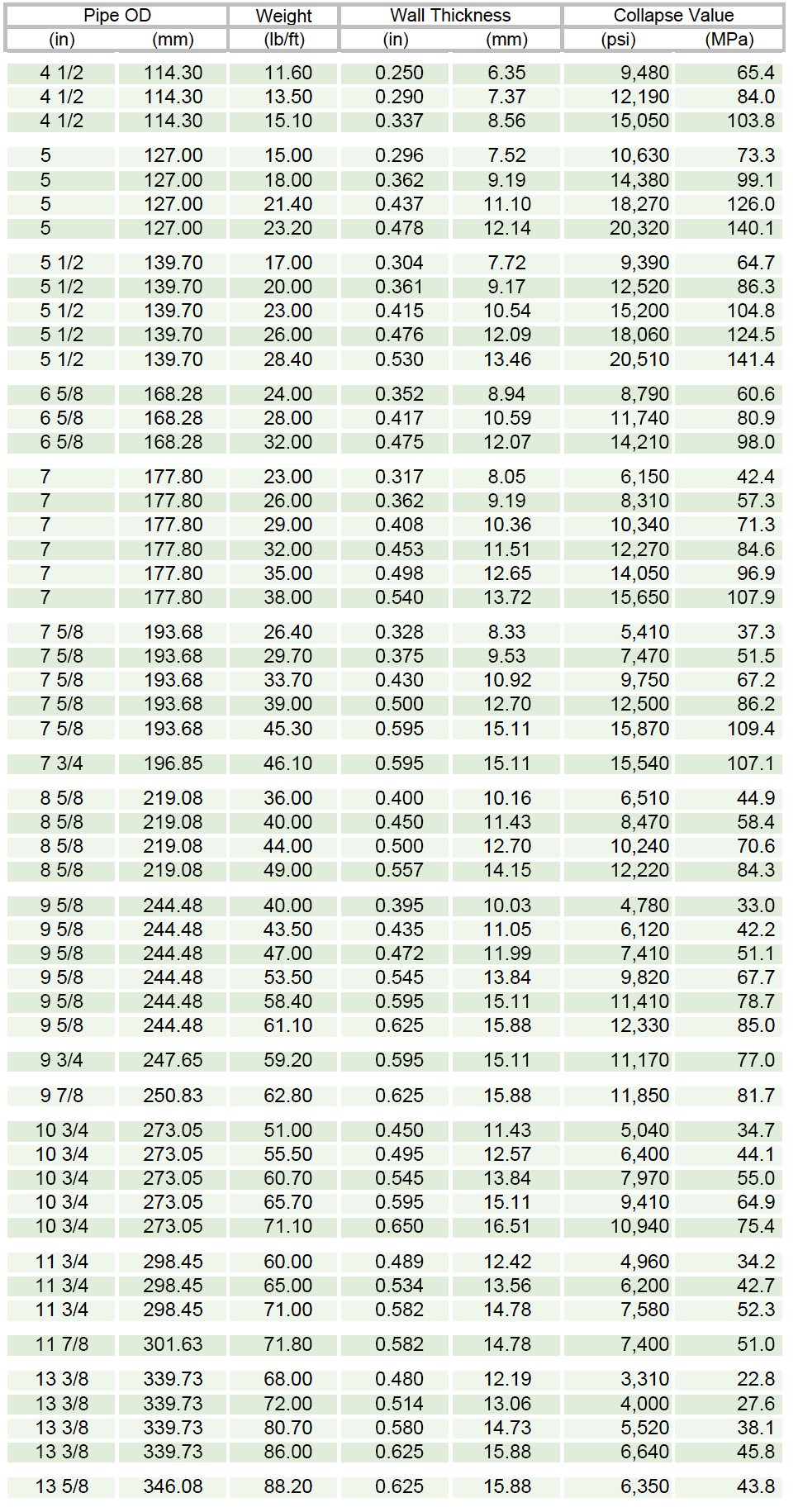

Diameters: 4 1/2” to 13 5/8”. Larger diameters available upon request.

Weights: as per API 5CT/ISO 11960

Special application: Please contact Nippon Steel engineer, should You require specific size, weight, drift, or any other information.

- Proprietary SMC110T.TGP-2915 (latest revision)

- API 5CT / ISO 11960

- NACE MR0175 / ISO 15156-2

- API 5C3 / ISO 10400

- API 5C1 / ISO 10405

- VAM Book

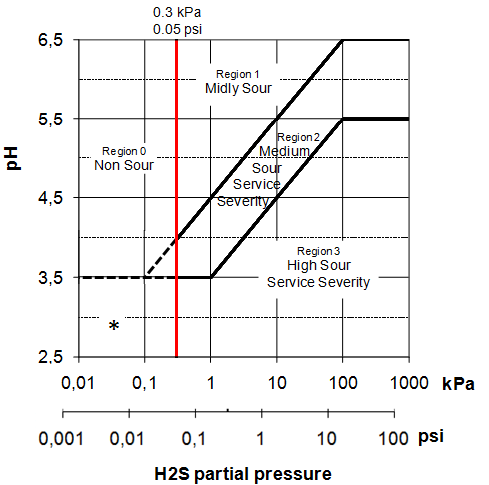

External Pressure driven applications in severe Sour Service environments corresponding to region 3, as defined by NACE MR0175/ISO15156-2 (Fig 1) :

Fig. 1 : Sour Service regions in the pH vs H2S diagram

* Note : Even though this low pH corner is considered non-sour as far as H2S is concerned, caution needs to be exercised, as High Strength materials may become susceptible to Environmental Cracking (EC) even with no or very limited H2S.

Sulfide Stress Cracking phenomenon is less critical when temperature increases (i.e. increasing depth), whereas problems associated with extreme external pressure conditions usually increases with depth. As a consequence, the necessity of SM-C110T usage results from the specific combination of unusually high pressure gradient and / or low temperature gradient. Typical applications are :

- Pre-salt formations, salt dome, clastic formation

- Wildcat drilling

In addition, enhanced collapse resistance can offer well design flexibility where controls of string weight and wall thickness are critically important:

- Tight clearance applications such as contingency drilling liners

- Oversized Drift for intermediate and production Casing

- Deep Offshore applications where slim and light design is critical

There is a fair amount of confusion in relation to the H2S partial pressure limit applicable to 110 ksi sour service material. ISO 15156 / NACE MR0175 stance toward this type of materials may be overly conservative limiting their usage to either Region 1 or in any H2S partial pressure as long as these materials are exposed to temperature always exceeding 65°C (150°F). On the other end, the general interpretation is to consider these materials wrongly “full fledge” sour service with no H2S limit at all temperature. Nippon Steel, for the moment being,recommends usage of SM-C110T in H2S environments with H2S partial pressures up to 1 bar, at all temperatures.

For each manufactured SM-C110T heat, SSC resistance is verified through physical testing in accordance with NACE TM0177 method A, in solution A, using an applied stress of 85% SMYS. Additionally, as part of SMI QA/QC system, using the same frequency as for the tensile test, a physical Collapse test is performed at the mill on each production run to ensure that the minimum declared material collapse properties are exceeded.

For a more detailed assessment please contact Nippon Steel engineers.

| PROCESS | DESCRIPTION |

|---|---|

| Steel making | Ladle refined, fully killed and vacuum degassed; continuously cast to a fine grained practice |

| Pipe making | Seamless |

| Heat treatment | Quenched and Tempered |

| YIELD STRENGTH KSI |

TENSILE STRENGTH KSI |

ELONGATION % |

HARDNESS HRC |

TECHNICAL NOTE | |

|---|---|---|---|---|---|

| Min | Max | Min | Min | Max | |

| 110 | 125 | 115 | API Formula | 30.0 | 85% SMYS 1bar H2S, NACE A, Solution-A Collapse: Refer to MDS / Tech Info |

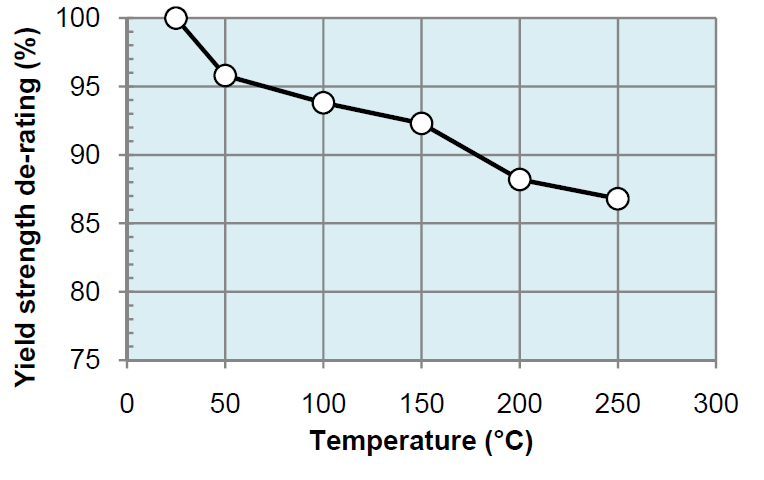

| UNIT | 25°C | 50°C | 100°C | 150°C | 200°C | 250°C | |

|---|---|---|---|---|---|---|---|

| Density | Kg/m3 | 7750 | 7740 | 7730 | 7720 | 7700 | 7680 |

| Young's modulus | GPa | 212 | 211 | 209 | 206 | 203 | 200 |

| Poisson's Ratio | - | 0.30 | 0.30 | 0.30 | 0.30 | 0.29 | 0.29 |

| Tensile strength de-rating | % | 100 | 96.3 | 94.3 | 95.2 | 95.2 | 95.2 |

| Yield strength de-rating | % | 100 | 95.8 | 93.8 | 92.3 | 88.2 | 86.8 |

| Thermal Diffusivity | x10-6 m2/s | 11.9 | 11.9 | 11.5 | 11.0 | 10.3 | 9.74 |

| Heat Capacity | x106 J/m3 deg.C | 3.49 | 3.61 | 3.72 | 3.83 | 3.97 | 4.17 |

| Thermal Conductivity | W/m deg.C | 41.5 | 42.9 | 42.8 | 42.1 | 40.9 | 40.6 |

| Specific Heat | J/Kg deg.C | 450 | 466 | 481 | 496 | 516 | 543 |

| Thermal expansion | x10-6 / deg.C | - | 12.5 | 12.3 | 12.4 | 12.6 | 12.8 |

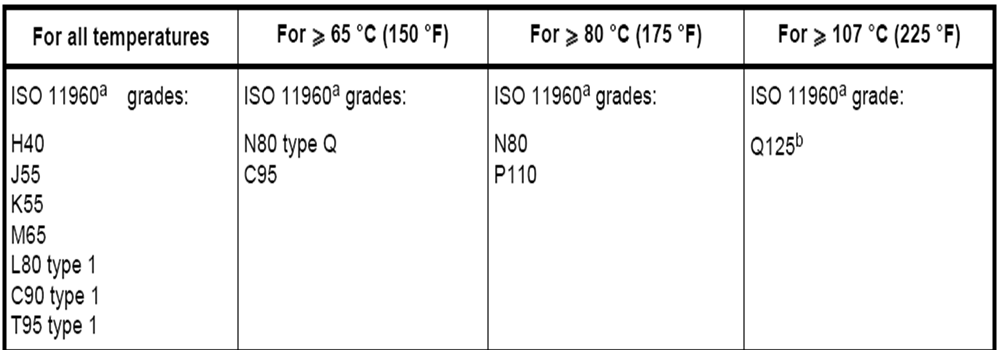

Temperature increase tends to minimize materials SSC susceptibility, and this tendency can be observed on API grades as well where, according to NACE MR0175 / ISO 15156-2, at higher temperature exposures high strength materials can be used in Region 3 of NACE MR0175/ISO15156-2 pH-H2S domain diagram (please refer to Fig 1).

Referring to API P110 grade in particular, this material can be used in high H2S environments if and only if the material is exposed to temperatures exceeding 80°C / 175°F (Fig. 2):

Fig. 2 : SSC Temperature thresholds for API Carbon steel grades according to NACE MR0175 / ISO 15156-2.

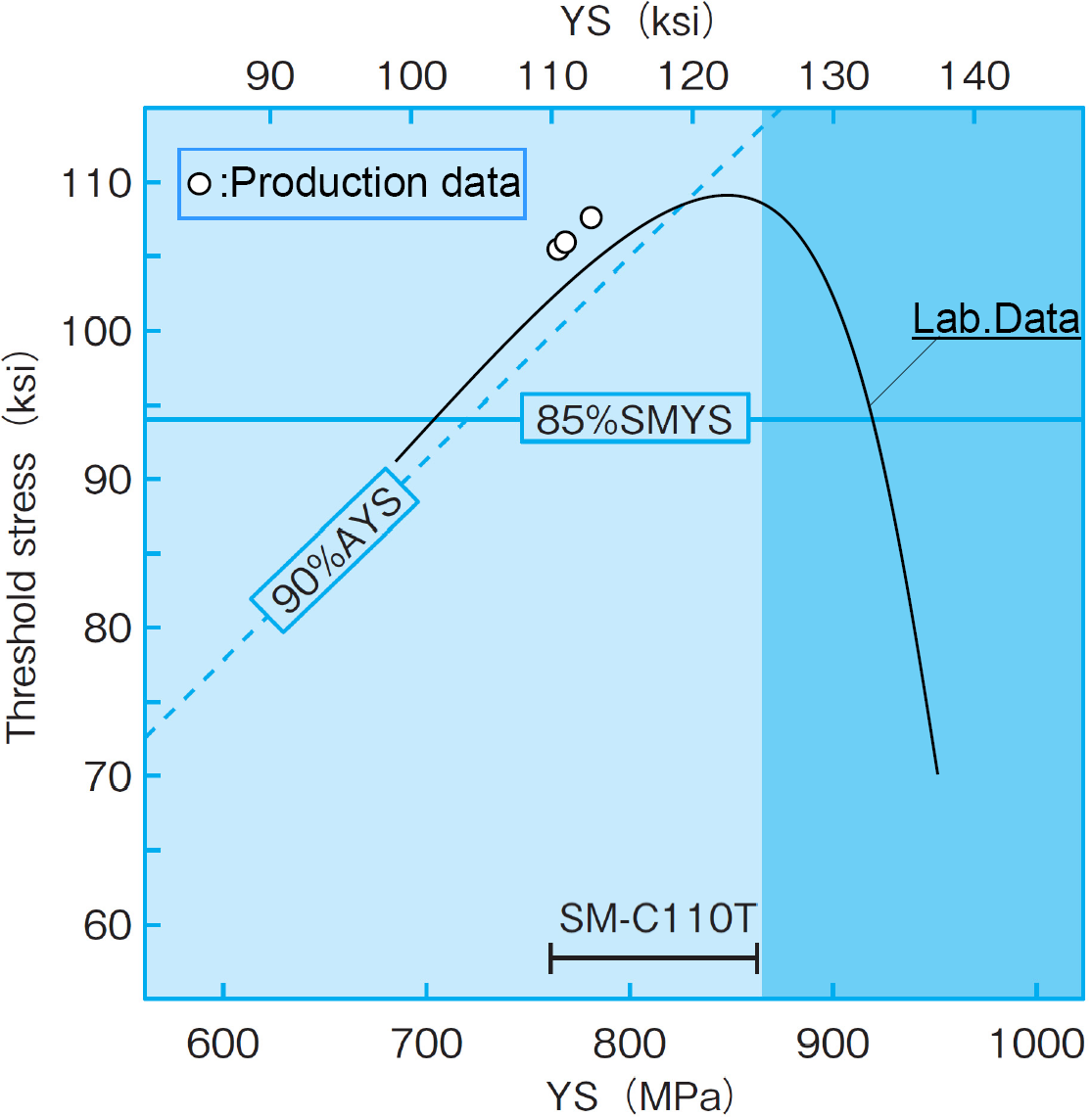

Figure 3 below shows the SSC results obtained on SM-C110 (1 bar H2Spp, NACE Method A, solution A) demonstrating the material's superior SSC resistance at ambient temperature, thus qualifying the material for all temperature applications. Sumitomo SSC extensive research program on SM-C110 was performed using NACE Method A in Solution A, loading the material at ≥ 90% of Actual Yield Strength (AYS) within its Specified Yield Strength range, allowing a safety margin versus the guaranteed material SSC performances set at 85% of Specified Minimum Yield Strength (85% SMYS, NACE Method A, Solution A).

SM-C110 superior SSC performances have been confirmed as well on mill produced material as shown in Figure 3.

Fig. 3 : SM-C110T SSC suceptibility to material Yield Strength and applied threshold stress.

NACE Method A, solution A, 25 deg.C.

SM-C110T is equivalent to SM-C110, produced using the same manufacturing route as SM-C110 with additional controls meant to achieve higher collapse resistance.

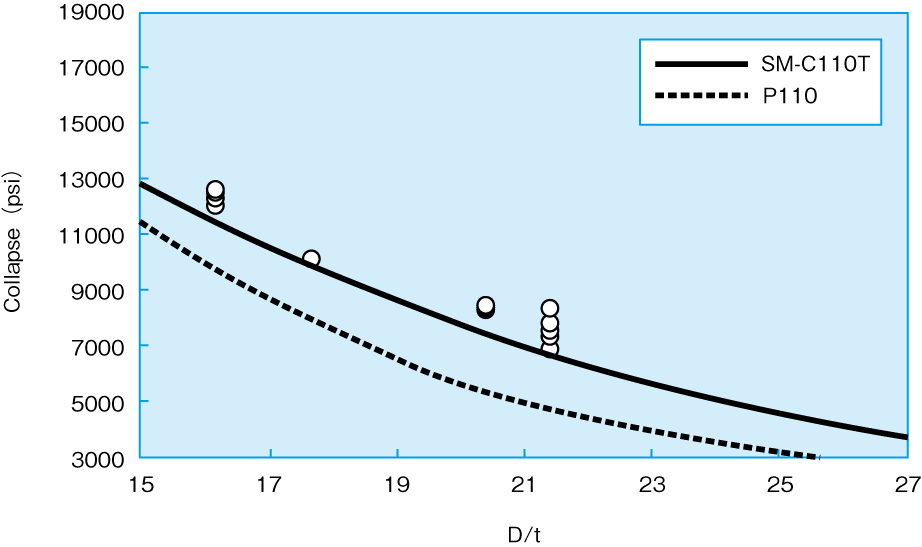

Pipe dimensions such as Diameter (D) or wall thickness (t) and mechanical characteristics such as the material Yield Strength are the first parameters dictating tubular Collapse resistance. Figure 4 specifically illustrates the commensurate influence of the D/t ratio (Diameter over wall thickness).

Nippon Steel, on SM-C110T High Collapse & Sour Service series, applies tighter tolerances to influential parameters, such as ovality, eccentricity, OD and wall thickness. In addition, a specific chemistry and strict heat treatment control are used to ensure steel structural homogeneity and low residual stresses.

Figure 4 demonstrates SM-C110T enhanced performances compared to API P110 collapse resistance (derived from API 5C3 / ISO 10400 formula), through its physical test results, guaranteeing the published minimum Collapse ratings.

Fig. 4 : Collapse pressure on SM-C110T versus API P110

Table 5 features SM-C110T High Collapse values for a large selection of pipe sizes. They exceed API P110 collapse ratings by a factor ranging from +15% to +40% !!! to be revised.

Table 5 : SM-C110T High Collapse values

Table 5 covers most common sizes and wall thicknesses; upon request Nippon Steel can provide larger sizes up to 16", specific or tailor-made sizes, weights or special drifts.

For additional information about material performances please contact Nippon Steel engineers.

Health, Safety and Environment

While state-of-the-art HSE rules are applied throughout Nippon Steel manufacturing process, proprietary and specific HSE regulations shall be applied along the life cycle of the pipe until it reaches its final position in the well, according to each operator’s rules. This particularly applies to all phases of handling and transportation, assembly on the rig floor, and rig return if applicable. OCTG are heavy and by nature unstable. Special care shall be paid to potential risks of injury whenever handling OCTGs. Walking on pipes shall be avoided at all times. Usage of Personal Protection Equipments (PPE) is mandatory. Equipment and procedures will be established to capture the possible wastes generated during maintenance (cleaning, coating, doping) and disposed according to local regulations. This applies in particular to storage dope, running dope, or cleaning water wastes.

Best practices for transportation, handling and storage of OCTG in general are covered by ISO 10405 / API RP5C1. VAM Book is also a good source of handling practices for VAM connections. In addition to these general rules, specific care is recommended pertaining to SMC110T, because improper handling could affect the material performances and by extension the corrosion resistance :

- Prevention of Spot Hardening

For more specific information please contact Nippon Steel engineers.