CRA Cold Drawn

|

|

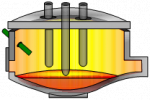

1. Electric Arc Furnace

Electric Arc Furnace operates as batch re-melting of recycled stainless steel. Nippon Steel strictly controls the chemical composition of the raw materials with a particular attention given to radioactive contaminants.

VOD |

AOD |

|

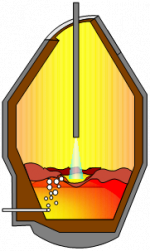

2. Refining

AOD stands for Argon Oxygen Decarburization process. Nippon Steel AOD process employs multiple oxygen blowing systems to effectively remove carbon from the hot liquid metal.

VOD stands for Vacuum Oxygen Decarburization process. This process is also meant to remove carbon while avoiding Chromium oxdation.

Nippon Steel, by combined usage of these refining facilities, has established the most effective processing routes for a wide range of stainless steels from 13% chrome to high nickel alloys.

|

|

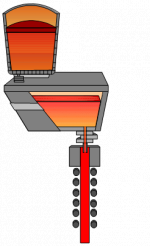

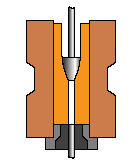

3. Casting

A vertical type continuous casting machine is employed in the stainless steel making plant. This CC machine, together with the unrivaled operating know-how, can provide extremely clean and low porosity blooms. Ingot casting can also be selected to optimize operational flexibility. Full traceability of each bloom or ingot is established to maintain the best quality control.

|

|

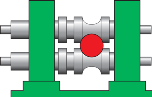

4. Billet making

Then Blooms are either rolled or forged into "billet". Processing temperature and reduction ratio are strictly controlled in this process.

Vertical press |

Horizontal press |

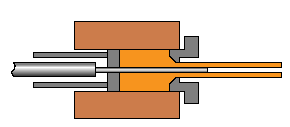

5. Mother pipe making

CRA tubing mother pipes are mainly produced by hot extrusion process. Nippon Steel mainly uses the “Ugine Sejourne” process which consists of 2 stages; a primary vertical press to enlarge the ID of the hollowed billet, followed by a high capacity horizontal press transforming the hollowed billet into a mother pipe.

Cold Drawing |

6. Cold drawing

From the hot produced mother pipe, CRA tubings are cold drawn to achieve the required physical properties, precise geometry, and excellent surface quality.

Non-Destructive |

Dimensional |

|

7. Inspection

After pipe making, produced pipes are thoroughly inspected. The most advanced non-destructive inspection facilities are employed to scan the whole pipe body length. Visual, dimensional inspection including drift test, and Hydrostatic test are also carried out to each pipe. Particular care is applied throughout the finishing processes, after final descaling to prevent Carbon steel contamination.

Threading |

Power Tightening |

|

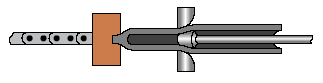

8. Threading

Both API & VAM premium connections are manufactured. Each dimensional parameter is controlled through the application of a stringent gauging process. Torque/Turn control is applied to all T&C VAM connections Coupling make-up.

Marking |

Packing |

|

Shipping |

||

9. Marking, Packing, Shipping

After threading, the finished products are marked for identification according to the requirements. Coating for atmospheric corrosion protection will be applied if necessary. As a final step, the pipes are securely packed for safe transportation.