Testing Facilities

Corrosion Testing Center

As the leading company in manufacturing specialty materials OCTG, Nippon Steel has a considerable corrosion testing capacity inclusive of NACE TM0177 A, B, C, D, SSRT, autoclaves and multipurpose test vessels.

NACE TM0177 Type A Testing Facilities

Hundreds of NACE A (Proof Ring) Test Cells are available:

- Each cell is placed in a nitrogen chamber to avoid oxygen contamination.

- Special equipments are used for tensile straining to avoid unnecessary torsion to the specimens.

- Low temperatures NACE A Tensile tests can be performed upon request.

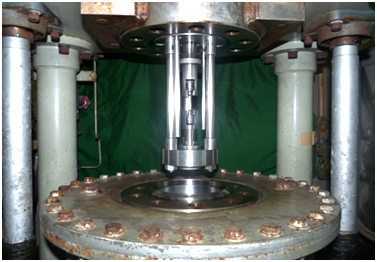

Autoclaves and Multi-purpose Test Vessels

For other type of corrosion tests, such as 3-points bend, 4-points bend, C-Ring, DCB (Double Cantilever Beam), SSRT (Slow Strain Rate Test), coupon exposure & crevice tests Nippon Steel retains a number of Autoclaves & Multi-purpose Vessels.

Other Material Test Facilities

Mechanical Test

Besides Tensile Testing (ambient condition & Elevated temperature), Charpy Impact, Hardness, Flattening, Drop Weight Tear Test (DWTT), Fatigue, Compressive, Collapse, Burst Testing, etc. can be performed in Nippon Steel Testing Facilities.

Chemical Analysis, Physical & Micro Analysis

Specific equipments such as EDXA (Energy Dispersion X-Ray Analyzer), EPMA (Electron Probe Micro Analyzer) and others are available for in depth fit for purpose analysis.

Heat Treatment

Simulation of Heat Treatment processes inclusive of Thermo-Mechanical, as well as post manufacturing heat input can be carried in lab sized heat treatment furnaces to validate new manufacturing procedures, and specific post manufacturing process evaluation.

Research Laboratory

Corporate R&D facilities are the foundation of Nippon Steel OCTG know how.

Besides the fundamental R&D programs, these laboratories are involved in:

- Evaluation of material performances such as

- Material strength & fatigue performances

- Corrosion resistance

- Magnetic performances

- Impact fracture analysis

- Computer analysis of

- Strength, fatigue and fracture mechanics

- Forming process

- Material structure and performance

- Heat and fluid analysis

- Failure analysis

- Material analysis to nano scale order

- Surface analysis

- Inclusion analysis

- Material structure and grain boundary analysis