Connection List

CLEANWELL® is an anti-corrosion and lubricating semi-dry system applied in the mill on the surface of VAM® threads. Developed for Carbon steel and Corrosion resistant alloy materials, CLEANWELL® is designed to prevent the use of thread compounds that have proved to damage the environment, affect health and safety or contaminate downhole equipments and producing formation . Using CLEANWELL® will generate no discharge nor unnecessary handling from the mill to the rig. Take off the protector and run it !

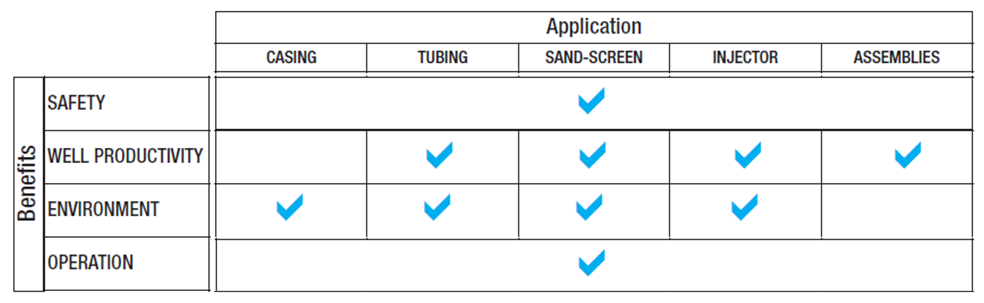

Benefits |

|---|

|

Your applications of choice

2,000,000 feet of CLEANWELL® have been so far ran successfully with the following applications :

Performances

- Storage : 12 months (up to 60°C)

- Running : 10 M&B in Tubing, 3 in Casing (As per ISO13679/API 5C5. Down to -30°C)

- Connection sealibility envelope : Unchanged

- Operating temperature downhole up to 180°C

Make-up

- Specific make-up torque table (maximum coefficient 1.6)

- Acceptance criterion of torque-turn graph : unchanged

- Compatible with rig fluid environment

- Compatible with API dope and VAM approved green dopes

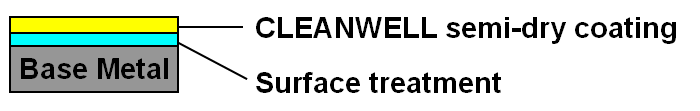

CLEANWELL® principle

CLEANWELL® is applied to the unchanged VAM connection geometry. It is composed of a surface treatment applied on the bare metal, with the superposition of the final semi-dry coating. Surface treatment is adapted to pin versus box pin and to the supporting bare material :

Available applications

- Carbon steel, 13CR, Super13CR and CRA

- VAM TOP, VAM TOP HC, VAM TOP HT, VAM SLIJ-II

Please contact us with your specific combination of material, size and connection.

Field practices

- Specific protector

- Tally and drifting recommendations

- Decontamination practices available