Connection List

CLEANWELL® DRY is an anti-corrosion and lubricating dry system applied in the mill on the surface of VAM® threads. Developed for Carbon steel and 13CR material, CLEANWELL® DRY is designed to prevent the use of thread compounds that have proved to damage the environment, affect health and safety or contaminate downhole equipments and producing formation . Using CLEANWELL® DRY will generate no discharge nor unnecessary handling from the mill to the rig. Take off the protector and run it !

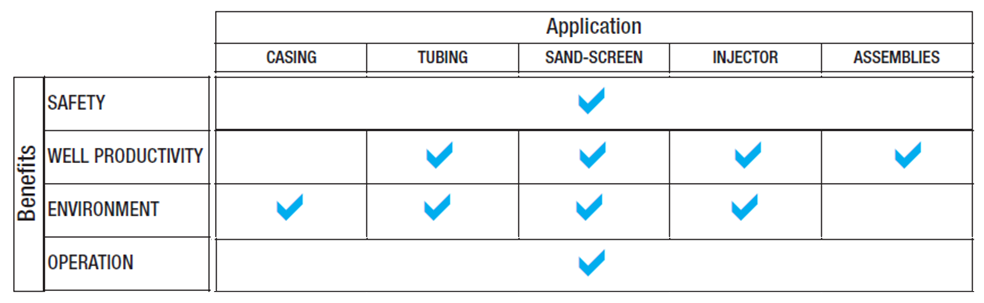

Benefits |

|---|

|

Your applications of choice

Performances

- Storage : 18 months *

- Running : 10 M&B in Tubing, 3 in Casing (As per ISO13679/API 5C5. Down to -30°C.)

- Connection sealibility envelope : Unchanged

- Operating temperature downhole up to 180°C

*Its performances highly depend on storage conditions & practices. As long as VAM® CLEANWELL® Dry is kept properly in storage, it is inspected periodically according to VAM® procedures, and it is found to be acceptable at Rig Prep stage, it can be safely used.

Make-up

- Specific make-up torque table (maximum coefficient 1.6)

- Acceptance criterion of torque-turn graph : unchanged

- Compatible with rig fluid environment

- Compatible with API dope and VAM approved green dopes

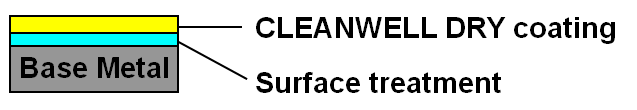

CLEANWELL® DRY principle

CLEANWELL® DRY is applied to the unchanged VAM connection geometry. It is composed of a surface treatment applied on the bare metal, with the superposition of the final dry coating. Surface treatment and final coating combinations are adapted to pin versus box pin and to the supporting bare material :

Available applications

- Carbon steel, 13CR

- VAM TOP, VAM TOP HC

Please contact us with your specific combination of material, size and connection.

Field practices

- Specific protector

- Tally and drifting recommendations

- Decontamination practices available