Material Data Sheet

High Collapse, High Strength - SM-125TT

SM-125TT is a Carbon steel OCTG material that provides best-in-class and guaranteed Collapse resistance compared to API ratings. In addition SM-125TT production order is delivered with a Collapse proof test.

API Collapse rating is an empirical guideline derived from Collapse testing results, on a statistical scale and conservatively using a worst case scenario approach. Actual Collapse resistance of OCTG seamless pipe is affected by a large number of parameters. Nippon Steel has developed an unrivaled know-how in mastering the most influential parameters, and interlocking with best-in-class quality control, tighter than API 5CT/ISO 11960.

Diameters: 4 1/2” to 13 5/8”. Larger diameters available upon request.

Weights: as per API 5CT/ISO 11960

Special application: Please contact Nippon Steel engineer, should you require specific size, weight, drift, or any other information.

- Proprietary SM-TT series.TGP-2945 (latest revision)

- API 5CT / ISO 11960

- API 5C3 / ISO 10400

- API 5C1 / ISO 10405

- VAM Book

External Pressure driven applications:

- Salt dome / clastic formation

- High Pressure - High Temperature well (HP-HT)

- Wildcat drilling

- Deep well

In addition, enhanced collapse resistance can offer well design flexibility where controls of string weight and wall thickness are critically important:

- Tight clearance applications such as contingency drilling liners

- Oversized Drift for intermediate and production Casing

- Deep Offshore applications where slim and light design is critical

As part of Nippon Steel QA/QC system, using the same frequency as for the tensile test, a physical Collapse test is performed at the mill on each production run to ensure that the minimum declared material collapse properties are exceeded.

In case Sour Service performances are required, SM-125S shall be considered.

For a more detailed assessment please contact Nippon Steel engineers.

| PROCESS | DESCRIPTION |

|---|---|

| Steel making | Ladle refined, fully killed and vacuum degassed; continuously cast to a fine grained practice |

| Pipe making | Seamless |

| Heat treatment | Quenched and Tempered |

| YIELD STRENGTH KSI |

TENSILE STRENGTH KSI |

ELONGATION % |

HARDNESS HRC |

TECHNICAL NOTE | |

|---|---|---|---|---|---|

| Min | Max | Min | Min | Max | |

| 125 | 155 | 135 | API Formula | N/A | Collapse: Refer to MDS / Tech Info |

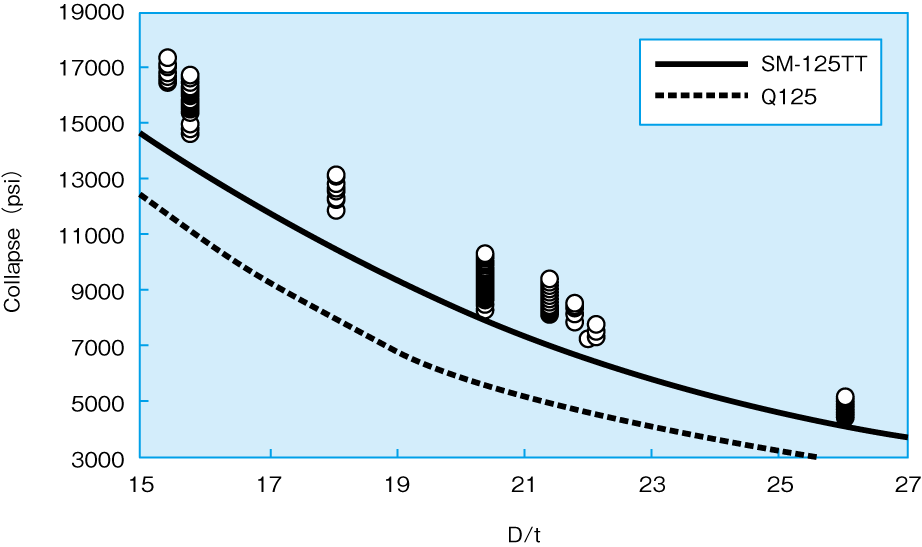

Pipe dimensions such as Diameter (D) or wall thickness (t) and mechanical characteristics such as the material Yield Strength are the first parameters dictating tubular Collapse resistance. Figure 1 specifically illustrates the commensurate influence of the D/t ratio (Diameter over wall thickness).

Nippon Steel, on SM-TT High Collapse series, applies the tightest tolerances to influential parameters, such as ovality, eccentricity, OD and wall thickness. In addition, a specific chemistry and strict heat treatment control are used to ensure steel structural homogeneity and low residual stresses.

Figure 1 demonstrates SM-125TT enhanced performances compared to API Q125 collapse resistance (derived from API 5C3 / ISO 10400 formula), through its physical test results, guaranteeing the published minimum Collapse ratings.

Fig. 1 : Collapse pressure on SM-125TT versus API Q125

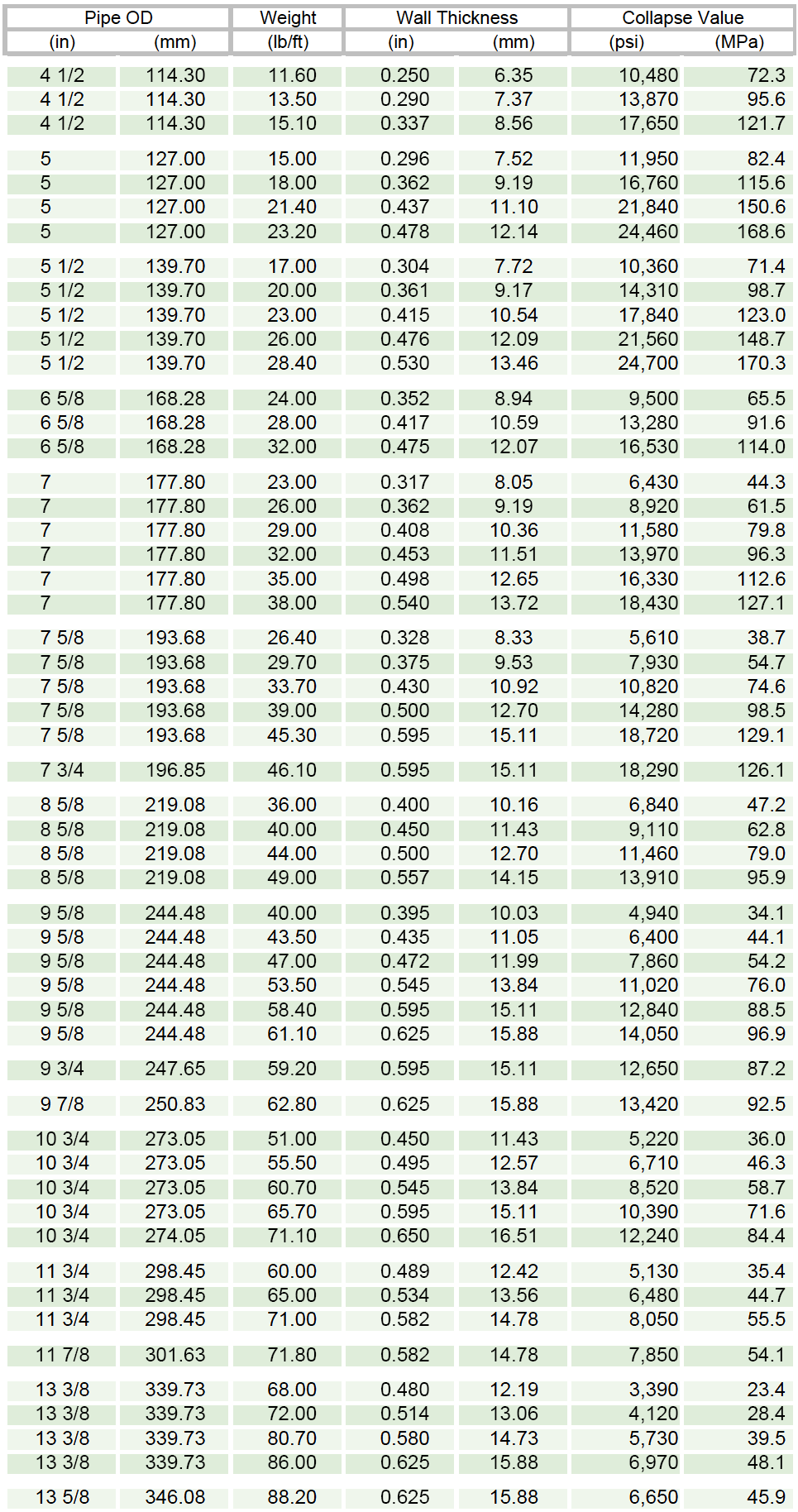

Table 2 features SM-125TT High Collapse values for a large selection of pipe sizes. They exceed API Q125 collpsee ratings by a factor ranging from +15% to +45%.

Table 2 : SM-125TT High Collapse values

Table 2 covers most common sizes and wall thicknesses; upon request Nippon Steel can provide larger sizes up to 16", specific or tailor-made sizes, weights or special drifts. The above referenced collapse ratings are provided as a minimum guideline, since SM-125TT is designed upon demand, and can be provided with tailored Collapse performances to meet costumer specific requirements.

For additional information about material performances please contact Nippon Steel engineers.

Health, Safety and Environment

While state-of-the-art HSE rules are applied throughout Nippon Steel manufacturing process, proprietary and specific HSE regulations shall be applied along the life cycle of the pipe until it reaches its final position in the well, according to each operator’s rules. This particularly applies to all phases of handling and transportation, assembly on the rig floor, and rig return if applicable. OCTG are heavy and by nature unstable. Special care shall be paid to potential risks of injury whenever handling OCTGs. Walking on pipes shall be avoided at all times. Usage of Personal Protection Equipments (PPE) is mandatory. Equipment and procedures will be established to capture the possible wastes generated during maintenance (cleaning, coating, doping) and disposed according to local regulations. This applies in particular to storage dope, running dope, or cleaning water wastes.

Best practices for transportation, handling and storage of OCTG in general are covered by ISO 10405 / API RP5C1. VAM Book is also a good source of handling practices for VAM connections.

For more specific information please contact Nippon Steel engineers.