Material Data Sheet

ERW Large OD Casing - NT-95DE

NT-95DE is a NIPPON STEEL proprietary Carbon Steel HF ERW (High Frequency Electric ResistanceWelded) OCTG material. This material provides superior impact toughness properties with YS (YieldStrength) ranging from 95 to 110 ksi and with a guaranteed min. wall thickness 92.5% of specified nominalWT. The high dimensional control & accuracy of wallthickness and outside diameter provide betterdriftability, internal yield pressure (burst) and collapse resistance.This material is a cost effective alternative to API 5CT / ISO 11960 R95 seamless material.

OD & Weights:as per API 5CT/ISO 11960, pleas e refer to Table 1. Material can be delivered in plain endconditions, API Connections or NSMAXTM GR Connections.

Special application:Please contact NIPPON STEEL engineers, should you require any specific size,weight, drift or any other information.

- Proprietary NT DE series: PT 41E (latest revision) API 5CT / ISO 11960

- API 5C3 / ISO 10400

- API RP 5C1 / ISO 10405

- Data Book for NSMAXTM GR Connection

Applications

- Deep Well

- HPHT Well

- Large Size Surface Casing & Conductor Casing

- Offshore environment to reduce rig time

- Subsea fatigue driven Surface Casing

- Shallow gas isolation

- Geothermal application

Characteristics

- High Strength and Superior Impact Toughness

- High External and Internal Pressure Resistance

- High Compression Resistance (for application in high temperature well)

- Better Drift ability

For more detailed assessment please contact NIPPON STEEL engineers

| PROCESS | DESCRIPTION |

|---|---|

| Steel making | Ladle refined, fully killed and vacuum degassed; continuously cast |

| Hot Coil Making | Hot rolled to high strength and toughness with a fine grained micro structure by Thermo-Mechanically Controlled Process |

| Pipe making | Cold formed, High-Frequency Electric resistance Welded (HF-ERW) |

| Heat treatment | Weld area only (no need of "full body heat treatment |

| Inspection & Testing | Based on API 5CT / ISO 11960(*) |

For specific requirements, please contact NIPPON STEEL engineers.

The manufacturing processof HF ERW with cold pipe forming provides high accuracy in wall thickness and ovality control. Furthermore, NIPPON STEEL has developed state of the art advanced automatic control method ofhighfrequency welding heat input and automatic NDI system to prev ent any weld defects. Integrated process computer system provides total quality control to comply with API / ISO or specific customer’srequirements through manufacturing to shipment.

(mass %)

| C | Si | Mn | P | S |

|---|---|---|---|---|

| ≤ 0.30 | ≤ 0.45 | ≤ 1.90 | ≤ 0.020 | ≤ 0.010 |

| YIELD STRENGTH KSI |

TENSILE STRENGTH KSI |

ELONGATION % |

HARDNESS HRC |

TECHNICAL NOTE | |

|---|---|---|---|---|---|

| Min | Max | Min | Min | Max | |

| 95 | 110 | 105 | API Formula | N/A | 92.5% of specified WT |

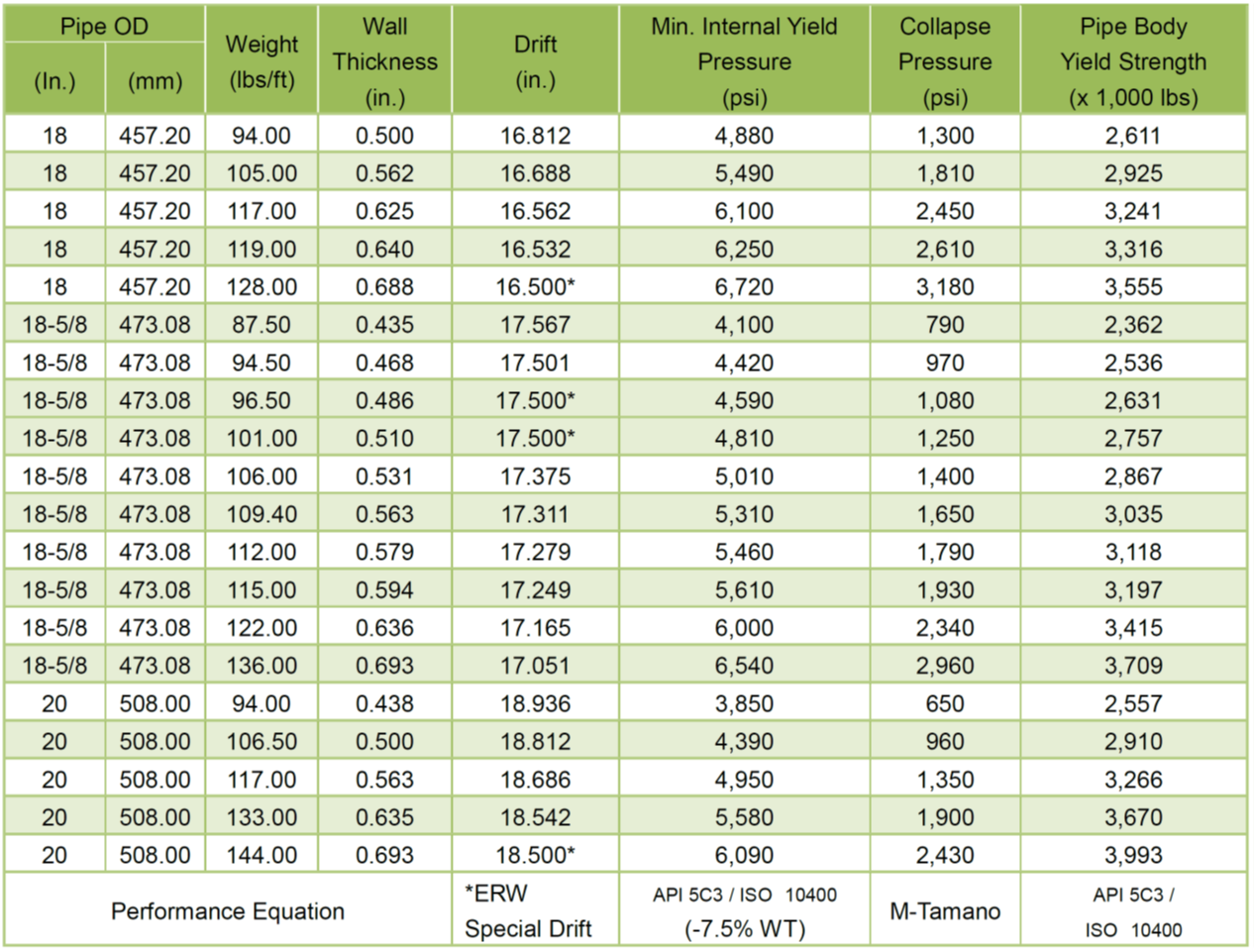

Pipe dimensions such as Diameter (D), wall thickness (t) or ovality and mechanical characteristics such asthematerial Yield Strength are the first parameters dictating tubular External Pressure (Collapse) andInternal Yield Pressure (Burst) resistance.

Table 1 features NT-95DE performance values and its available selection of pipe sizes.

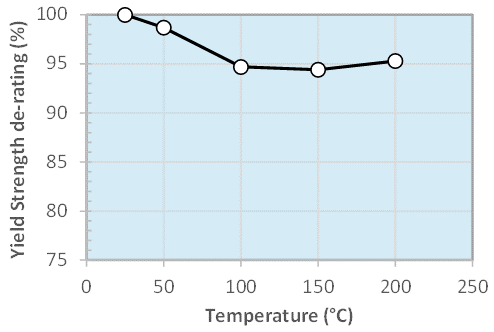

| UNIT | 25°C | 50°C | 100°C | 150°C | 200°C | 250°C | |

|---|---|---|---|---|---|---|---|

| Density | Kg/m3 | 7830 | 7830 | 7810 | 7800 | 7780 | |

| Young's modulus | GPa | 208 | 207 | 205 | 202 | 199 | |

| Poisson's Ratio | - | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 | |

| Tensile strength de-rating | % | 100.0 | 98.7 | 94.7 | 94.1 | 96.4 | |

| Yield strength de-rating | % | 100.0 | 99.9 | 94.4 | 94.4 | 95.3 | |

| Thermal Diffusivity | x10-6 m2/s | 10.7 | 10.5 | 10.2 | 9.88 | 9.49 | |

| Heat Capacity | x106 J/m3 deg.C | 3.55 | 3.64 | 3.81 | 3.94 | 4.07 | |

| Thermal Conductivity | W/m deg.C | 38.0 | 38.3 | 39.0 | 39.1 | 38.9 | |

| Specific Heat | J/Kg deg.C | 453 | 465 | 488 | 506 | 523 | |

| Thermal expansion | x10-6 / deg.C | - | 12.1 | 12.4 | 13.0 | 13.4 |

Health, Safety and Environment

While state of the art HSE rules are applied throughout NIPPON STEEL’s manufacturing process, it is important that specific HSE policies are applied along the life of the pipe until it reaches its final position inthe well. These policies should be developed according to each operator’s rules. This applies to all phases of handling, transportation, assembly on the rig floor, and rig return if applicable. OCTG are heavy and by nature unstable. Special attention shall be paid to potential risks of injury whenever handling OCTG. Walking on pipes shall be avoided at all time. Usage of Personal Protection Equipment (PPE) is mandatory. Equipment and procedures will be established to capture the possible wastes generated during maintenance (cleaning, coating, doping) and disposed according to local regulations. This applies in particular to storage dope, running dope, or cleaning water wastes. General best practices for transportation, handling and storage of OCTG in general are covered by ISO10405 / API RP5C1. NSMAXTM GR Recommended Running Manual & Rig Preparation is also a good source of handling practices for NSMAXTM GR Connections. For more specific information please contact NIPPON STEEL engineers